Niezależnie od tego, czy potrzebujeszMaszyna do laminowania na zamówienie, kompletnyMaszyna do laminowania paneli boazeryjnychlub zautomatyzowanego sprzętu zwiększającego produkcję, nasi inżynierowie są tutaj, aby pomóc Ci zaprojektować idealne rozwiązanie.📧E-mail:pattypeng@purmachinefactory.com

🌐

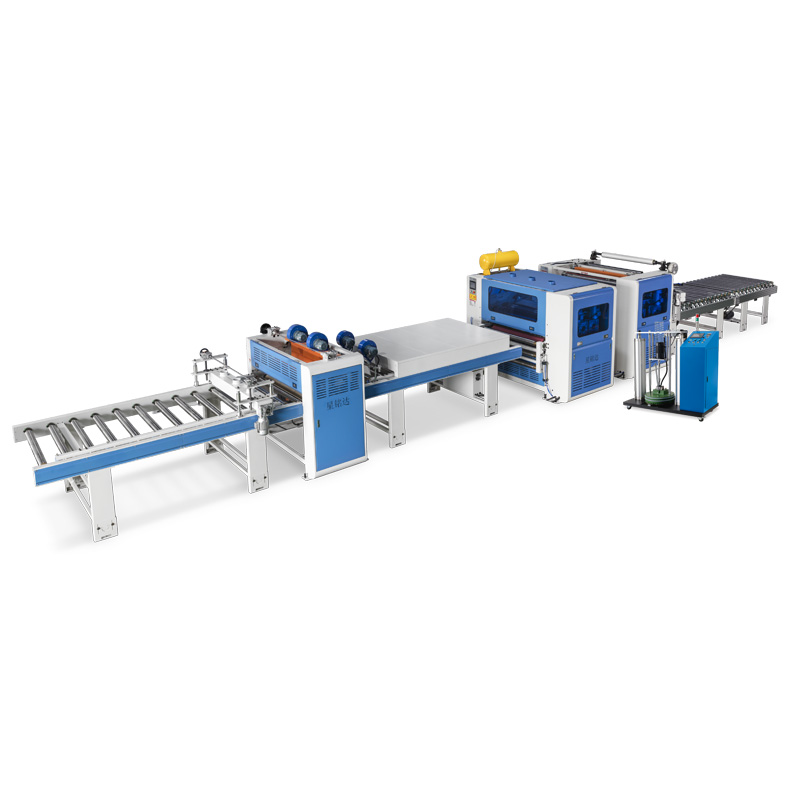

Strona internetowa:www.purmachinefactory.comTwórzmy lepsze, mocniejsze i piękniejsze panele — razem.3 mm and 7 mm, offering flexibility for diverse panel applications. Every stage of the workflow has been fine-tuned to deliver stable bonding and high-quality surface finishing.

1. Dust Removal: Electrostatic Brushing & Air Blowing

As the panel enters the conveyor, it first passes through a single-sided electrostatic brush, effectively lifting and collecting micro dust particles. This prevents impurities from affecting adhesion. An air-blowing device follows immediately, ensuring a clean, residue-free surface ready for lamination.

2. Pre-Heating: 1-Meter Heating Tunnel

The panel then moves into a 1-meter oven, allowing gentle pre-heating. This step improves glue activity and ensures consistent temperature before entering the gluing section—especially important for thin wainscotting boards that respond sensitively to sudden heat changes.

3. Precision Gluing: Even Surface Application

Inside the dedicated Gluing Machine, adhesive is applied uniformly across the panel surface. This even coating is crucial for avoiding bubbles, slips, and surface inconsistencies during pressing.

4. Active Glue Heating & Manual Veneer Placement

After gluing, the machine’s heating oven keeps the glue active long enough for operators to manually position veneer sheets. This hybrid approach—machine precision + manual control—gives manufacturers exceptional flexibility, particularly for decorative wainscotting patterns.

5. Pressing for Firm Bonding

The panel then enters the pressing unit, which stabilizes the bond and ensures a smooth, wave-free finish. Adhesive, temperature, and pressure systems work together to lock the veneer firmly into place.

6. Corona Treatment for Stronger Adhesion

A built-in corona machine enhances surface tension, significantly improving film adhesion. This ensures that decorative films, PVC surfaces, and veneer materials remain firmly attached over long service cycles.

7. Final Output

Once completed, the finished panel exits the machine fully laminated—clean, smooth, and ready for follow-up processing or direct installation.

This Customized Lamination Machine demonstrates Xingmingda’s ability not only to produce reliable equipment but also to adapt every detail to customer needs.

About Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd.

Founded in 2004 in Lunjiao Town—China’s renowned woodworking machinery hub—Xingmingda has dedicated itself to the development of automatic woodworking machinery including:

Wrapping machines

Edge-banding machines

Slotting machines

Hot-melt coating machines

PUR lamination machines

Cold glue and hot glue wrapping systems

Customized lamination solutions for panel surfaces

With CNC production equipment, strict quality control, and a culture focused on professionalism and integrity, the company consistently delivers durable, stable, and practical machinery trusted in both domestic and global markets.

Today, Xingmingda’s machines continue to support manufacturers with dependable technology and customer-driven innovation.

Industry Analysis: Lamination Equipment Market Outlook

| Category | Industry Trend | Key Factors | Impact on Lamination Machine Development |

| Growth of decorative wall panels | Strong | Home renovation & commercial interiors | Higher demand for Lamination Machine for Wainscotting Panel |

| Customization in woodworking | Rapid | Project-based production | Increased need for Customized Lamination Machine solutions |

| Precision bonding requirements | Rising | Veneer, PVC, film upgrades | More advanced gluing and pre-heating systems |

| Automation adoption | Accelerating | Labor cost & efficiency | Growth in automatic woodworking machinery |

| Sustainability concerns | Expanding | Low-VOC adhesives & eco-materials | Improved energy-efficient heating and dust-cleaning systems |

FAQ

1. What materials can this lamination machine handle?

It supports wainscotting panels ranging 3–7 mm, including MDF, PVC surface boards, and veneer-ready substrates.

2. Why is pre-heating important for thin panels?

It stabilizes temperature, increases glue activation, and prevents warping or uneven bonding.

3. What is the function of the corona device?

It enhances surface energy and significantly improves adhesion between film/veneer and board.

4. Can the machine be further customized?

Yes. Conveyor length, oven size, glue type, feeding width, and automation features can all be tailored.

5. Is this equipment suitable for small workshops?

Absolutely. It is compact, highly stable, and efficient—ideal for both medium-sized factories and specialized panel producers.

Conclusion

The rise of modern wall décor has made wainscotting panels a must-have product, and achieving premium finish quality requires dependable machinery. Xingmingda’s Customized Lamination Machine for Wainscotting Panel blends precision, flexibility, and operator-friendly design—ensuring consistent bonding and superior surface performance.

Backed by years of expertise in automatic woodworking machinery, Xingmingda remains committed to innovation, stability, and customer-focused solutions.

Ready to Upgrade Your Lamination Process?

Whether you need a Customized Lamination Machine, a complete Lamination Machine for Wainscotting Panel, or automated equipment to boost production, our engineers are here to help you design the perfect solution.

📧 Email: pattypeng@purmachinefactory.com

🌐 Website: www.purmachinefactory.com

Let’s build better, stronger, and more beautiful panels—together.